Ford Kuga Service ManualBody Repairs - General Information » Joining Techniques

Ford Kuga Service ManualBody Repairs - General Information » Joining Techniques

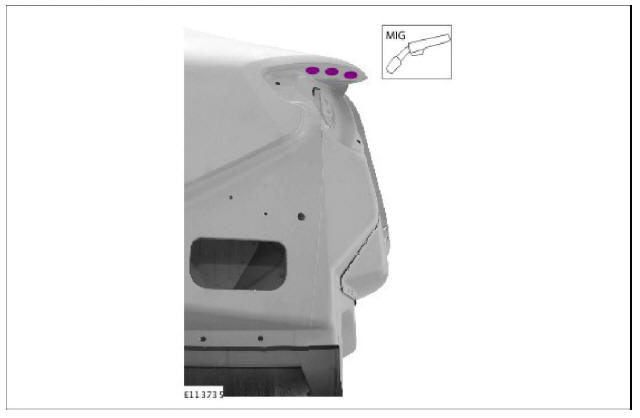

MIG brazes

MIG brazes

Basically, three methods of MIG welding are used:

- Puddle weld.

- Continuous bead welding

- Intermittent bead welding

Fields of application

- Any joins that are MIG welded in production must also be replaced by MIG welds

- Puddle welding may be used in certain cases, if there is insufficient access.

- If the overall panel thickness is greater than 3 mm, without correspondingly powerful spot welding equipment, puddle welding should be used.

- When dealing with any MIG brazed joints which are present, follow the vehicle-specific repair instructions.

NOTE: The increased application of heat during MIG welding destroys the corrosion protection layers over a much larger area than during resistance spot welding. For this reason, greater care must be taken when applying the corrosion protection afterwards.

Welding repairs can only be carried out properly if the equipment is set up correctly and all welding-related preparations are complied with accurately.

- Please note the instructions of the respective welding equipment manufacturer

- The hose assembly must be untwisted

- The core must be free from particles of wire debris.

- The gas and current nozzles must be free of slag and scale residue.

- Pay attention to the quality of the welding wire and the gas flow rate.

- Ensure that the joint surface is perfect.

- Prepare a bare metal joint surface.

- Maintain the correct gaps (root formation).

- Produce a test weld.

Plug Weld

Special features to note when puddle welding:

- The panels to be joined must lie perfectly flat to one another.

- The panel flanges must be treated with corrosion protection. The position of the weld must be bare.

- Prepare the holes depending on the thickness and number of the panels. The hole size should be 6-10 mm, or match the original weld spot

- Start the welding procedure on the panel at the bottom so that the hole is filled completely.

Continuous bead welding

A welded joint with a full seam is suitable for joining highly profiled body parts. Pillar and sill areas are typical application areas.

Special features to note during bead welding:

- Both parts of the panel must be bare on both sides over a width of 5 mm.

- Align the parts precisely with clamps.

- To prevent the panel from warping, tack longer joints before welding them.

Intermittent bead welding

Intermittent bead welding is used when the connecting flanges are stepped. This form of seam is mainly used on the external panel area for sectional repairs.

Special features to note when intermittent bead welding'

- Weld gap.

- Spot weld interval.

- Apply alternate tack welding across the entire length of the seam. This keeps warping to a minimum.

Joining techniques

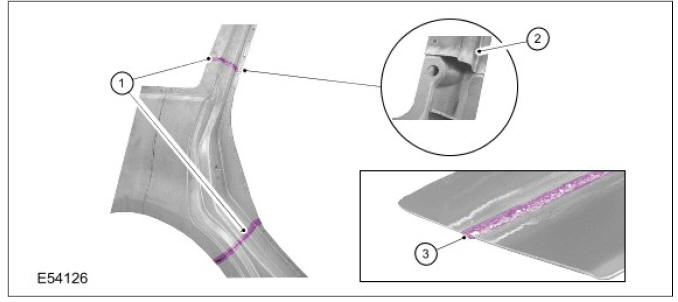

Butt joints

| Des cript ion | Description |

| 1 | Join areas |

| 2 | Profile |

| 3 | Full seam |

The butt joint is a joining technique frequently used in body repairs. The butt joint is typically used for repairs in the pillar and rocker panel area.

Areas that are suitable for the use of the butt joint:

- short seam lengths.

- highly profiled structures

The edges of the panels to be joined are placed against each other and are joined with a full seam in whilst maintaining a required welding gap (welding gap same as panel thickness).

NOTE: The butt joint requires a high degree of accuracy and care when trimming and cutting. For correct execution of the welding, an exact, even welding gap must be maintained.

Preparation of the joint areas includes:

- Sanding the connection areas bare on both sides.

- Removal of the zinc layer in the welding area.

- Carrying out welding tests on an equivalent sample panel before the actual welding, if necessary.

- Tack welding in the join area: From the edges to the centre, then check the shape.

- Joining new and old parts with a full seam weld.

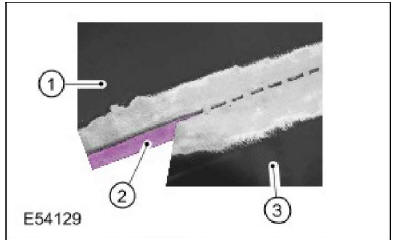

Joggled joint

| Description | Description |

| 1 | Body part |

| 2 | Joggled area |

| 3 | New panel |

The joggled joint variant is restricted to body areas with a good surface condition without beads/swage lines or profiles. A sectional replacement with a joggled joint is welded using a continuous seam.

This procedure is used, for example, at the transition from the side panel to the rocker panel (3-door vehicles).

When cutting the new part, slight measuring tolerances are permitted, as these are covered by the joggled area.

Preparation of the joint areas includes:

- Sanding the connection areas bare on both sides.

- Removal of the zinc layer in the welding area.

- Preparation of a joggled strip.

- Carrying out welding tests on an equivalent sample panel before the actual welding, if necessary.

- Joining the new and old panel with continuous seam welding.

- Lead loading the weld seam.

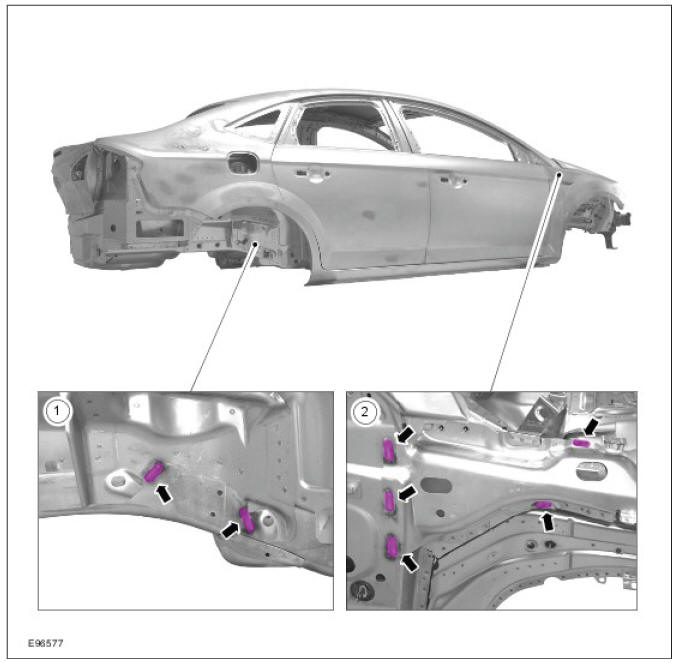

MIG brazes

| Des cript ion | Description |

| 1 | Rear side member/wheelhouse reinforcement |

| 2 | Apron panel reinforcement/A-pillar |

Metal Inert Gas (MIG) brazing is increasingly used in production for certain body areas.

In areas where resistance spot welding is not possible due to limited space or higher strength requirements, MIG welding was previously used.

Increasingly, these MIG welded seams are being replaced by MIG brazes. The temperature range used during MIG brazing is significantly lower. This keeps the damage to the anti-corrosion zinc layer on zinc-coated panels to a minimum.

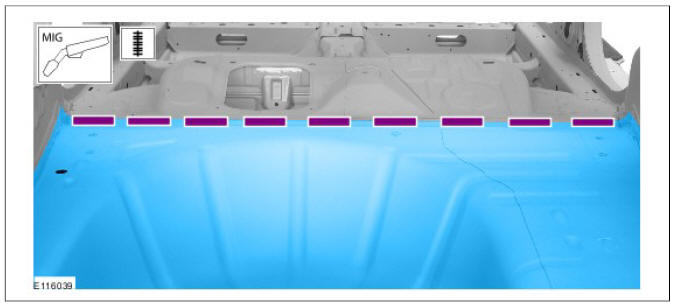

This results in the following advantages of the MIG brazed seam:

- No corrosion of the brazed seam.

- Low erosion of the zinc coating in the joining area.

- Low level of heating and thus little warping.

- Easy finishing of the brazed seam.

- Good for bridging gaps.

Technicians performing MIG brazing must use a Ford-certified MIG brazing device and must have been given appropriatetraining on the brazing techniques which are used.

Only use the Ford-approved brazing solder SG-CuSi3 (SG-CuSi3Mn1).

Unless specified otherwise, a minimum gap of 30 mm must be maintained between the MIG brazed seam and any adhesive bonds.

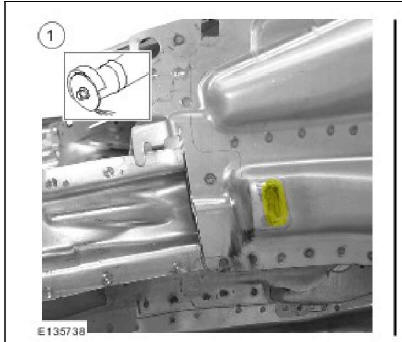

| Des cript ion | Description |

| 1 | Preparation of the MIG brazing: Flatten the old brazed seam with a grinder. |

| 2 | Preparation of the MIG welding: Grind the old brazed sean and the surrounding area until they are clean, and remove any residue of the brazed seam. |

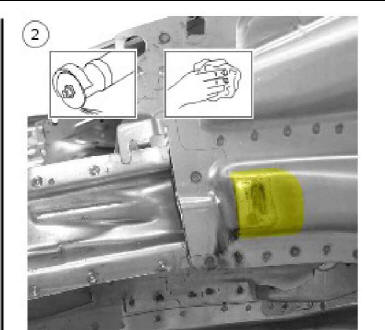

CAUTION: MIG welds must not be carried out on or near existing MIG brazed seams as even the smallest amount of brazing solder can result in a reduction in the strength of the weld seam.

If MIG brazing cannot be used then the factory-installed MIG brazed joints should be replaced with MIG welds in a different place during service repairs. These MIG welds must not be carried out on or in the immediate vicinity of existing MIG brazed seams as even the smallest amount of brazing solder can result in a reduction in the strength of the weld seam. Consequently, the corresponding graphics offer two alternative repair techniques (1: MIG brazing; 2: MIG welding).

| Description | Description |

| 1 | MIG brazing: Braze a new seam in the same place as the factory location for the seam. |

| 2 | MIG welding: Weld the seam away from the location of the factory-installed MIG brazed seam. |

Apart from in the locations used in production, MIG brazing can also be performed on non load-bearing outer body skin panels and floor panels.

CAUTION: Without prior approval from Ford, MIG brazing must not be performed on structural parts of the chassis or body.

Welding

Resistance spot welding

MIG brazes

Soft soldering

Rivets

Bonding

Bonding and welding

Bonding and riveting

Ford Kuga Service Manual

- General Information

- Jacking and Lifting

- Noise, Vibration and Harshness

- Suspension System - General Information

- Climate Control

- Auxiliary Climate Control

- Instrument Cluster and Panel Illumination

- Instrument Cluster

- Horn

- Warning Devices

- Parking Aid

- Charging System - General Information

- Battery, Mounting and Cables

- Generator and Regulator

- Voltage Converter/Inverter

- Information and Entertainment System - General Information

- Information and Entertainment System

- Exterior Lighting

- Interior Lighting

- Daytime Running Lamps (DRL)

- Module Communications Network

- Module Configuration

- Wiring Harnesses

- Anti-Theft - Active

- Anti-Theft - Passive

- Multifunction Electronic Modules

- Front End Body Panels

- Body Closures

- Interior Trim and Ornamentation

- Exterior Trim and Ornamentation

- Rear View Mirrors

- Seating

- Glass, Frames and Mechanisms

- Instrument Panel and Console

- Handles, Locks, Latches and Entry Systems

- Wipers and Washers

- Bumpers

- Safety Belt System

- Supplemental Restraint System

- Body Repairs - General Information

- Body Repairs - Vehicle Specific Information and Tolerance Checks

- Front End Sheet Metal Repairs

- Roof Sheet Metal Repairs

- Side Panel Sheet Metal Repairs

- Rear End Sheet Metal Repairs

- Paint - General Information

- Uni-Body, Subframe and Mounting System

- Suspension System - General Information

- Front Suspension

- Rear Suspension

- Wheels and Tires

- Driveshaft

- Rear Drive Axle/Differential

- Front Drive Halfshafts

- Rear Drive Halfshafts

- Brake System - General Information

- Front Disc Brake

- Rear Disc Brake

- Parking Brake and Actuation

- Hydraulic Brake Actuation

- Power Brake Actuation

- Anti-Lock Control

- Anti-Lock Control - Stability Assist

- Steering System - General Information

- Power Steering

- Steering Linkage

- Steering Column

- Steering Column Switches

- Engine System - General Information

- Engine- 2.5L Duratec (147kW/200PS) - VI5

- Engine Cooling

- Fuel Charging and Controls-2.5L Duratec (147kW/200PS) - VI5

- Fuel Charging and Controls - Turbocharger- 2.5L Duratec (147kW/200PS) - VI5

- Accessory Drive - 2.5L Duratec (147kW/200PS) - VI5

- Starting System- 2.5L Duratec (147kW/200PS) - VI5

- Engine Ignition - 2.5L Duratec (147kW/200PS) - VI5

- Engine Emission Control - 2.5L Duratec (147kW/200PS) - VI5

- Intake Air Distribution and Filtering - 2.5L Duratec (147kW/200PS) - VI5

- Evaporative Emissions

- Electronic Engine Controls

- Automatic Transmission/Transaxle

- Transmission/Transaxle Cooling

- Automatic Transmission/Transaxle External Controls

- Transfer Case

- Exhaust System-

- Fuel System

- Fuel Tank and Lines

- Acceleration Control

- Speed Control

- Climate Control System

- Climate Control

Main Categories

0.0072