Ford Kuga Service ManualBody Repairs - General Information » Joining Techniques

Ford Kuga Service ManualBody Repairs - General Information » Joining Techniques

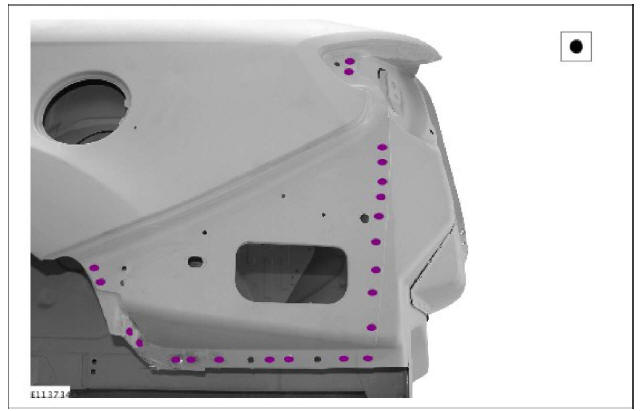

Resistance spot welding

Resistance spot welding

NOTE: Before starting the work, please refer to the chapter on safety instructions.

In doing so, the repair welds must match the standard of those produced in production in number and diameter.

Preconditions for resistance spot welding:

- The panels to be welded overlap

- The weld spot is accessible on both sides for the electrodes.

- The shape and alignment of the weld electrodes is correct.

- The resistance welding equipment is powerful enough to be able to reproduce the production spot weld diameter.

NOTE: The welding equipment settings and the adjustment of the individual parameters are to be made in accordance with the device manufacturer's specifications.

Well-prepared welding flanges are a prerequisite for a problem-free welded joint. This means:

- The welding flanges must lie perfectly flat to one another.

- The welding flanges must be clean and free of oil or grease on both sides.

- Welding primer (zinc-coated and conductive) must be applied as corrosion prevention.

Only in limited cases can welding errors in resistance spot weld joints be detected from the outside . Therefore, a test weld should be carried out before each repair weld. The peel test carried out after the welding gives information on the quality of the welding. The spot weld itself must never separate, it must tear away leaving a hole.

Welding

Resistance spot welding

MIG brazes

Soft soldering

Rivets

Bonding

Bonding and welding

Bonding and riveting

Ford Kuga Service Manual

- General Information

- Jacking and Lifting

- Noise, Vibration and Harshness

- Suspension System - General Information

- Climate Control

- Auxiliary Climate Control

- Instrument Cluster and Panel Illumination

- Instrument Cluster

- Horn

- Warning Devices

- Parking Aid

- Charging System - General Information

- Battery, Mounting and Cables

- Generator and Regulator

- Voltage Converter/Inverter

- Information and Entertainment System - General Information

- Information and Entertainment System

- Exterior Lighting

- Interior Lighting

- Daytime Running Lamps (DRL)

- Module Communications Network

- Module Configuration

- Wiring Harnesses

- Anti-Theft - Active

- Anti-Theft - Passive

- Multifunction Electronic Modules

- Front End Body Panels

- Body Closures

- Interior Trim and Ornamentation

- Exterior Trim and Ornamentation

- Rear View Mirrors

- Seating

- Glass, Frames and Mechanisms

- Instrument Panel and Console

- Handles, Locks, Latches and Entry Systems

- Wipers and Washers

- Bumpers

- Safety Belt System

- Supplemental Restraint System

- Body Repairs - General Information

- Body Repairs - Vehicle Specific Information and Tolerance Checks

- Front End Sheet Metal Repairs

- Roof Sheet Metal Repairs

- Side Panel Sheet Metal Repairs

- Rear End Sheet Metal Repairs

- Paint - General Information

- Uni-Body, Subframe and Mounting System

- Suspension System - General Information

- Front Suspension

- Rear Suspension

- Wheels and Tires

- Driveshaft

- Rear Drive Axle/Differential

- Front Drive Halfshafts

- Rear Drive Halfshafts

- Brake System - General Information

- Front Disc Brake

- Rear Disc Brake

- Parking Brake and Actuation

- Hydraulic Brake Actuation

- Power Brake Actuation

- Anti-Lock Control

- Anti-Lock Control - Stability Assist

- Steering System - General Information

- Power Steering

- Steering Linkage

- Steering Column

- Steering Column Switches

- Engine System - General Information

- Engine- 2.5L Duratec (147kW/200PS) - VI5

- Engine Cooling

- Fuel Charging and Controls-2.5L Duratec (147kW/200PS) - VI5

- Fuel Charging and Controls - Turbocharger- 2.5L Duratec (147kW/200PS) - VI5

- Accessory Drive - 2.5L Duratec (147kW/200PS) - VI5

- Starting System- 2.5L Duratec (147kW/200PS) - VI5

- Engine Ignition - 2.5L Duratec (147kW/200PS) - VI5

- Engine Emission Control - 2.5L Duratec (147kW/200PS) - VI5

- Intake Air Distribution and Filtering - 2.5L Duratec (147kW/200PS) - VI5

- Evaporative Emissions

- Electronic Engine Controls

- Automatic Transmission/Transaxle

- Transmission/Transaxle Cooling

- Automatic Transmission/Transaxle External Controls

- Transfer Case

- Exhaust System-

- Fuel System

- Fuel Tank and Lines

- Acceleration Control

- Speed Control

- Climate Control System

- Climate Control

Main Categories

0.0076