Ford Kuga Service ManualEngine- 2.5L Duratec (147kW/200PS) - VI5

Ford Kuga Service ManualEngine- 2.5L Duratec (147kW/200PS) - VI5

Engine

Engine

Assembly

Special Tool(s) / General Equipment

|

303-1054 Locking Tool, Timing Belt Tensioner |

|

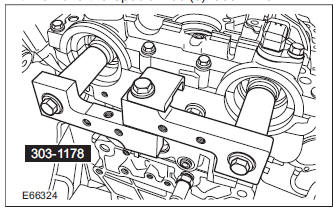

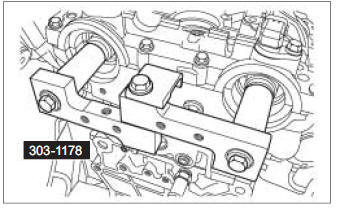

303-1178 Timing Tool Camshaft |

|

303-1179 Holding Wrench, Crankshaft |

|

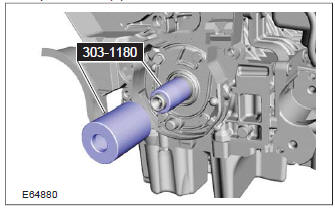

303-1180 Installer, Crankshaft Front Seal |

|

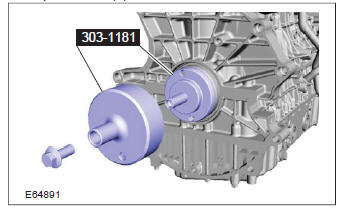

303-1181 Installer, Crankshaft Rear Seal |

|

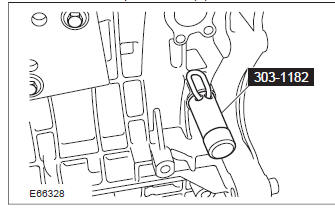

303-1182 Timing Tool, Crankshaft |

|

303-318 Aligner/Installer, Crankshaft Front Seal |

Piston Ring Compressor

Round-Ended Steel Rule

Materials

| Name | Specification |

| Engine Oil - 5W-30 | WSS-M2C913-C |

| Flange Sealant - Anaerobic LP | WSK-M2G348-A7 / 5U7J-M2G348-BA |

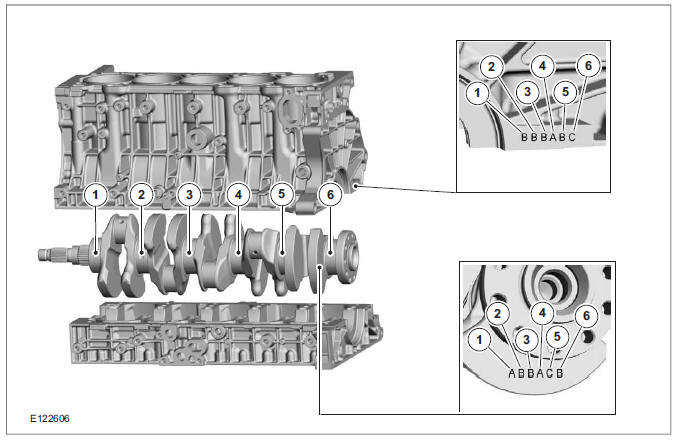

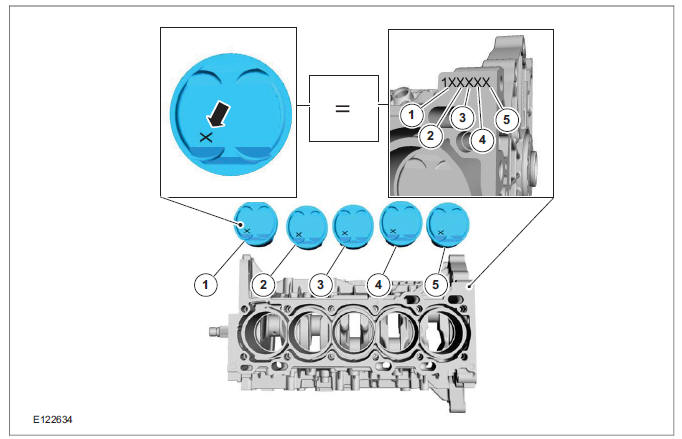

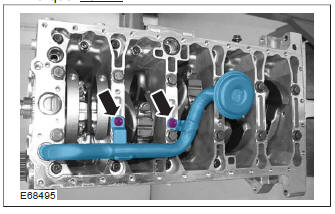

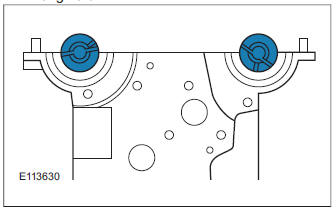

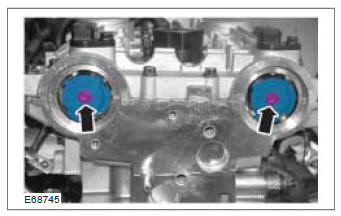

1. NOTE: This step is only necessary when installing a new component.

Refer to: Specifications (303-01 Engine - 2.5L Duratec (147kW/200PS) - VI5, Specifications).

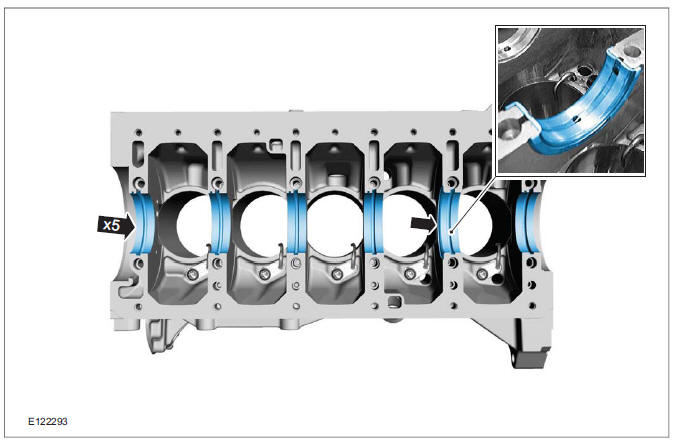

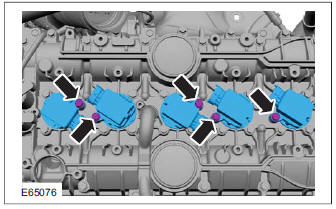

CAUTION: Make sure that the components are installed to the position noted before removal.

Apply a thin coating.

Material: Engine Oil - 5W-30 (WSS-M2C913-C) engine oil

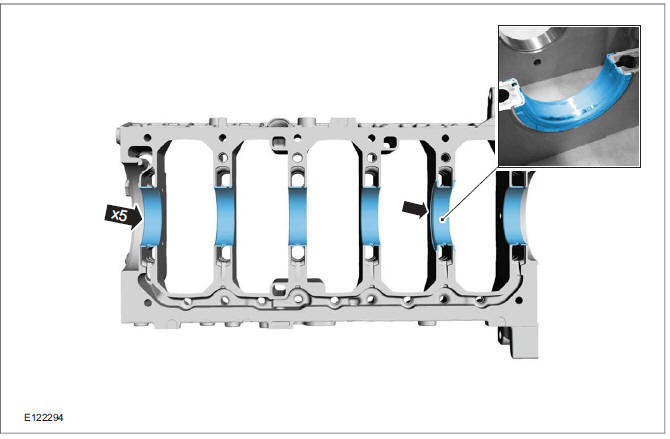

CAUTION: Make sure that the components are installed to the position noted before removal.

Apply a thin coating.

Material: Engine Oil - 5W-30 (WSS-M2C913-C) engine oil

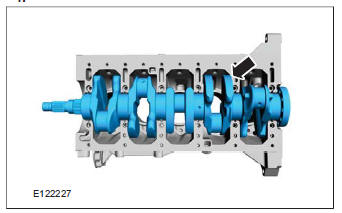

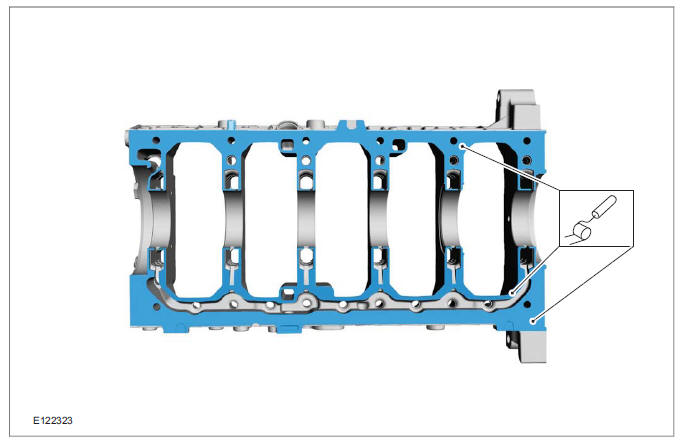

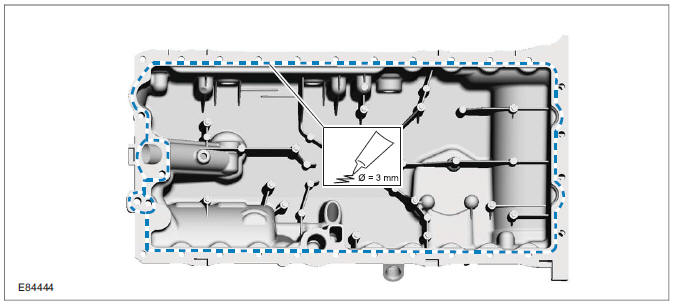

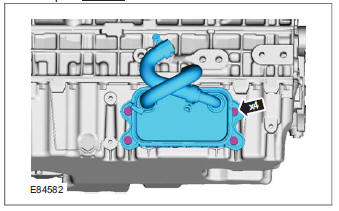

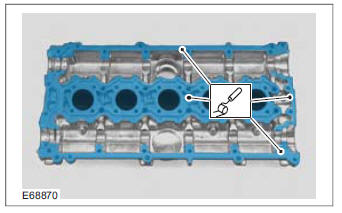

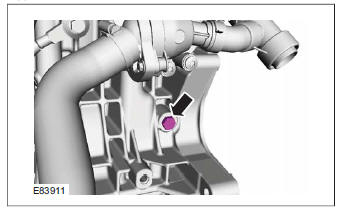

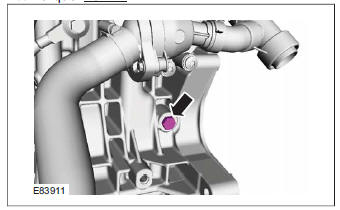

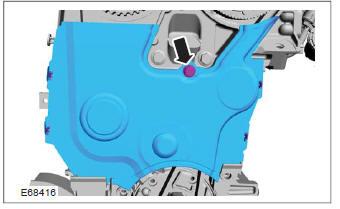

5. NOTE: The component must be installed within 5 minutes of applying the sealant.

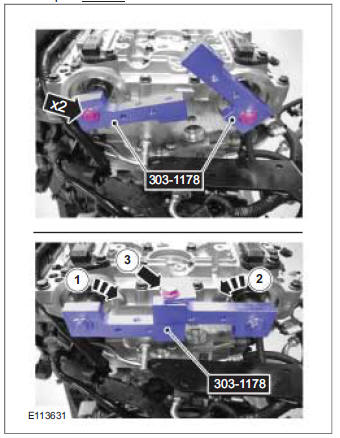

Material: Flange Sealant - Anaerobic LP (WSK-M2G348-A7 / 5U7J-M2G348-BA) sealant

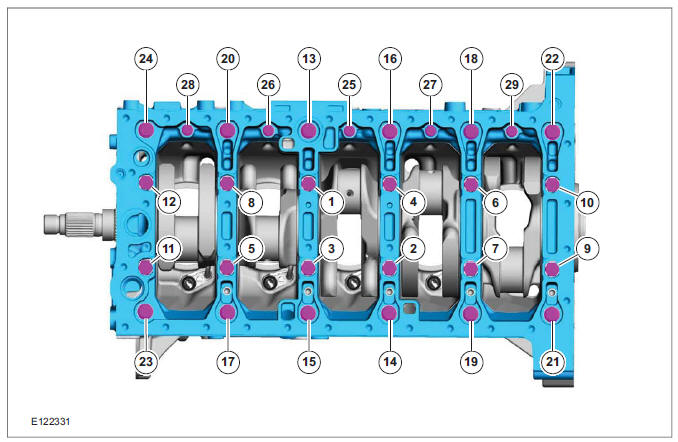

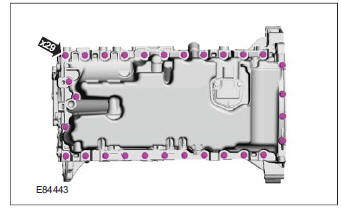

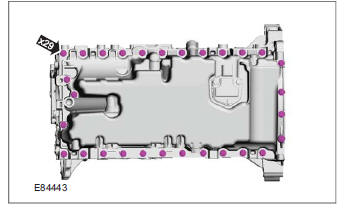

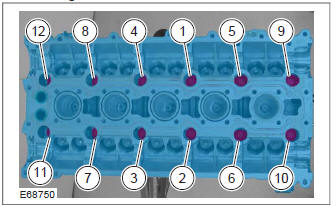

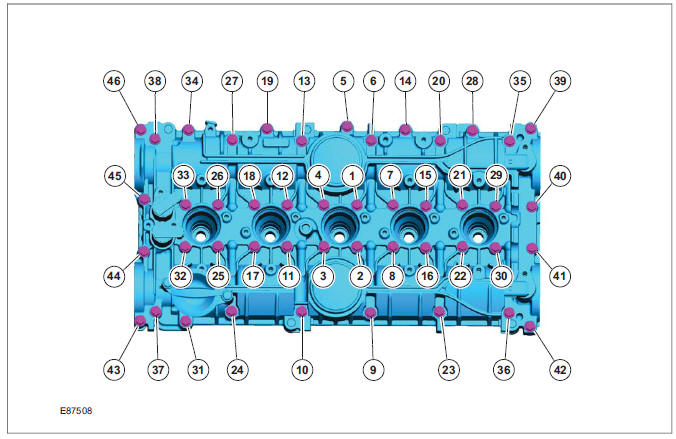

CAUTION: Make sure that new bolts are installed.

Torque:

- Stage 1: M10: 1-12 20 Nm

- Stage 2: M10: 1-12 45 Nm

7. Torque:

- M8: 13-24 24 Nm

8. Torque:

- M7: 25-29 17 Nm

9. Torque:

- M10: 1-12 90

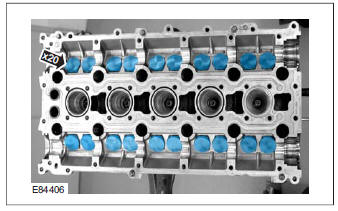

10.NOTE: This step is only necessary when installing a new component.

CAUTION: Make sure that the components are installed to the position noted before removal.

General Equipment: Piston Ring Compressor

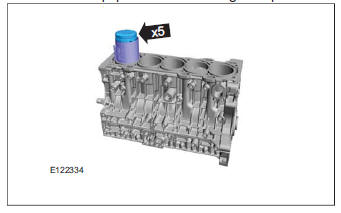

CAUTION: Make sure that the components are installed to the position noted before removal.

Apply a thin coating.

Material: Engine Oil - 5W-30 (WSS-M2C913-C) engine oil

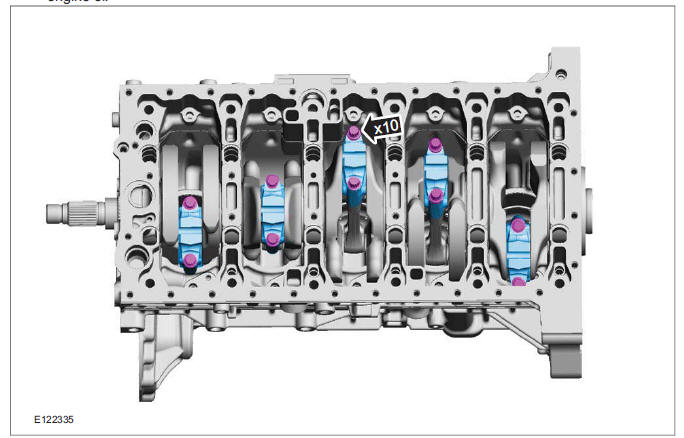

13.CAUTIONS:

- Make sure that the components are installed to the position noted before removal.

- Make sure that new bolts are installed.

Apply a thin coating.

Material: Engine Oil - 5W-30 (WSS-M2C913-C) engine oil

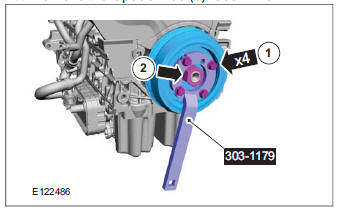

Torque:

- Stage 1: 30 Nm

- Stage 2: 90

14.Torque: 10 Nm

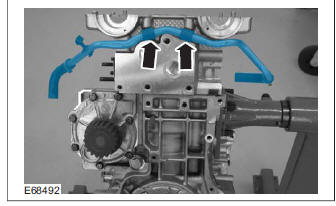

15.NOTE: The component must be installed within 5 minutes of applying the sealant.

Material: Flange Sealant - Anaerobic LP (WSK-M2G348-A7 / 5U7J-M2G348-BA) sealant

16.NOTE: Only tighten the bolts finger tight at this stage.

17. General Equipment: Round-Ended Steel Rule

18.Torque: 17 Nm

19.Torque: 17 Nm

20.Torque: 6 Nm

21. Special Tool(s): 303-1180

22. Special Tool(s): 303-1181

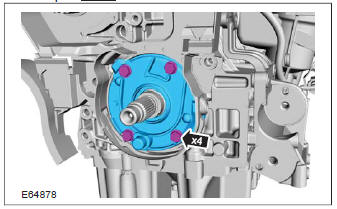

23.Torque:

- Stage 1: 20 Nm

- Stage 2: 60 Nm

- Stage 3: 130

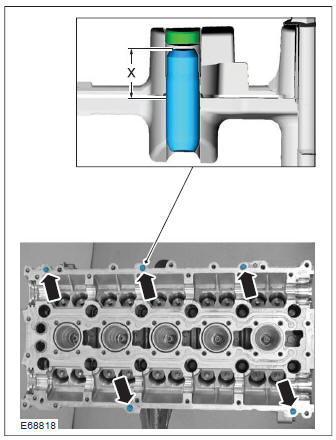

24. - X = 15 mm.

27. Apply a thin coating.

Material: Engine Oil - 5W-30 (WSS-M2C913-C) engine oil

28. Material: Flange Sealant - Anaerobic LP (WSK-M2G348-A7 / 5U7J-M2G348-BA) sealant

29.Torque: 17 Nm

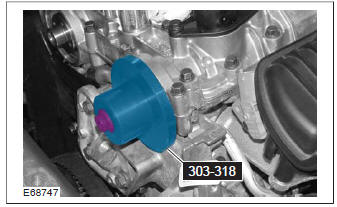

30. Special Tool(s): 303-318

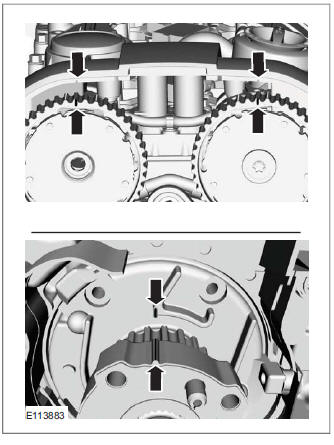

31.NOTE: The crankshaft timing pulley can only be installed in 1 position on the crankshaft splines.

Torque: 17 Nm

32.NOTE: Only tighten the bolts finger tight at this stage.

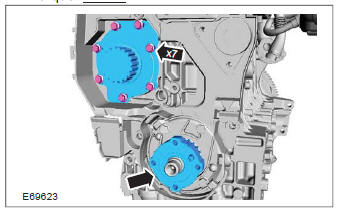

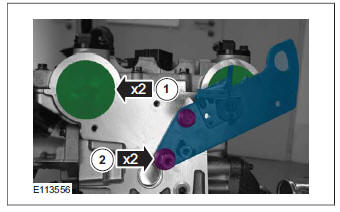

33. 1. Torque: 25 Nm

2. Torque: 12 Nm

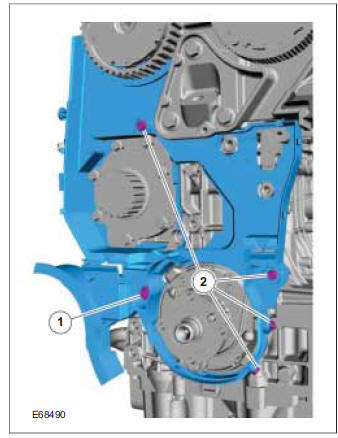

34.NOTE: Install all the bolts finger tight before final tightening.

1. Torque:

- Stage 1: 35 Nm

- Stage 2:75

2. Torque:

- Stage 1: 15 Nm

- Stage 2: 90

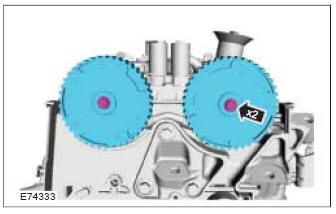

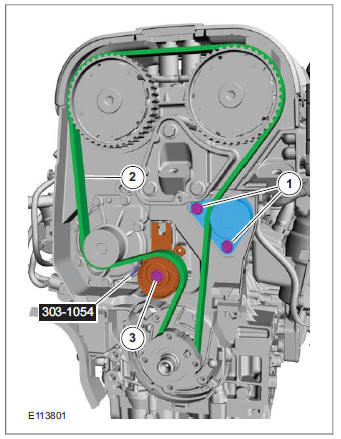

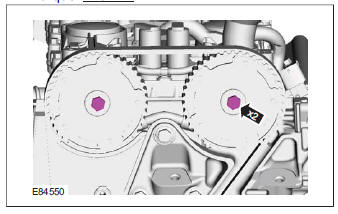

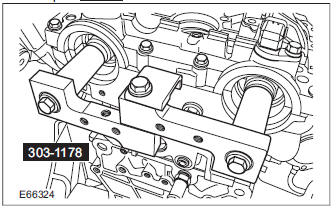

35. Install the Special Tool(s): 303-1178

Torque: 10 Nm

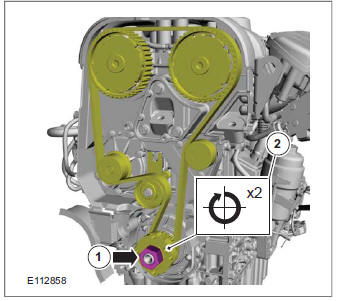

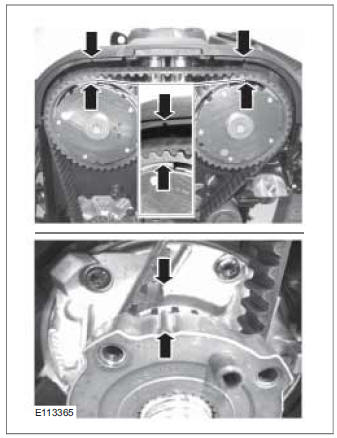

CAUTION: Only rotate the crankshaft clockwise.

Rotate the crankshaft slowly until the crankshaft stops.

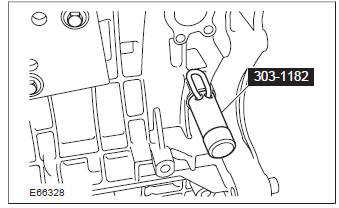

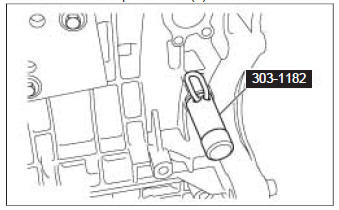

Install the Special Tool(s): 303-1182

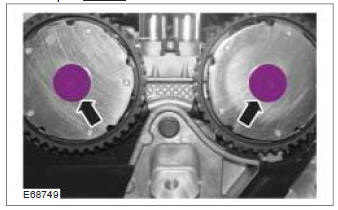

CAUTION: Make sure that the installation marks are aligned.

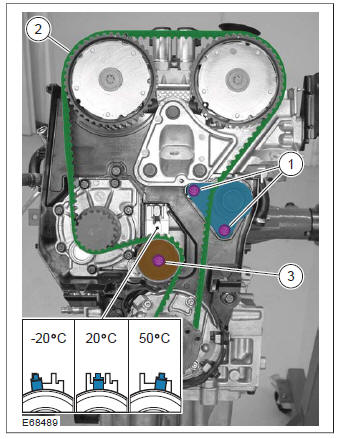

Vehicles with mechanical timing belt tensioner 39.NOTE: Make sure that new components are installed.

1. Torque: 25 Nm

3. Torque: 25 Nm

Vehicles with automatic timing belt tensioner 40.NOTE: Make sure that new components are installed.

1. Torque: 25 Nm

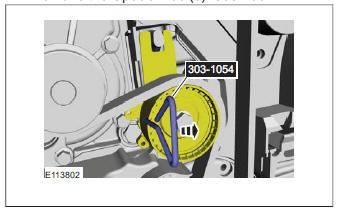

3. Special Tool(s): 303-1054

Torque: 25 Nm

WARNING: Take extra care when handling the compressed spring.

Remove the Special Tool(s): 303-1054

All vehicles

42.Torque: 120 Nm

43.Remove the Special Tool(s): 303-1178

CAUTION: Only rotate the crankshaft clockwise.

Rotate the crankshaft slowly until the crankshaft stops.

Remove the Special Tool(s): 303-1182

CAUTION: Only rotate the crankshaft clockwise.

Rotate the crankshaft slowly until the crankshaft stops.

Install the Special Tool(s): 303-1182

47. Install the Special Tool(s): 303-1178 Torque: 10 Nm

CAUTION: Make sure that the installation marks are aligned.

49.Torque: 35 Nm

50.Remove the Special Tool(s): 303-1182

51.Remove the Special Tool(s): 303-1178

53.Torque: 40 Nm

54. NOTE: Make sure that new components are installed.

2. Torque: 40 Nm

55.Torque: 10 Nm

56.Torque: 10 Nm

57. NOTE: Only tighten the bolts finger tight at this stage.

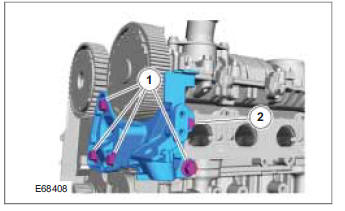

Install the Special Tool(s): 303-1179 1.

2. Torque: 180 Nm

58.Remove the Special Tool(s): 303-1179

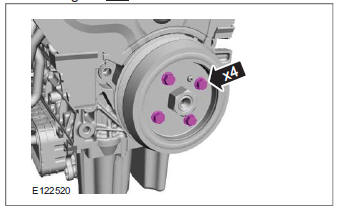

59.Torque:

- Stage 1: 25 Nm

- Stage 2: 60

Engine (Component Location)

Engine (Overview)

Engine (System Operation and Component Description).

Valve Clearance Adjustment

Intake Manifold (21 183 0) Removal

Crankshaft Front Seal (21 467 0)

Valve Stem Seals (21 238 0)

Timing Belt (21 304 0)

Camshafts (21 284 0)

Camshaft Seal (21 288 0)

Oil Pan (21 154 0)

Oil Pump (21 714 0)

Exhaust Manifold (21 187 0)

Cylinder Head (21 163 0)

Crankshaft Rear Seal (21 468 4)

Oil Cooler

Engine - Vehicles With: 5-Speed Automatic Transaxle (AW55)

Engine Accessories

Engine

Cylinder Head

Engine

Engine Accessories (21 139 4)

Engine - Vehicles With: 5-Speed Automatic Transaxle (AW55)

Ford Kuga Service Manual

- General Information

- Jacking and Lifting

- Noise, Vibration and Harshness

- Suspension System - General Information

- Climate Control

- Auxiliary Climate Control

- Instrument Cluster and Panel Illumination

- Instrument Cluster

- Horn

- Warning Devices

- Parking Aid

- Charging System - General Information

- Battery, Mounting and Cables

- Generator and Regulator

- Voltage Converter/Inverter

- Information and Entertainment System - General Information

- Information and Entertainment System

- Exterior Lighting

- Interior Lighting

- Daytime Running Lamps (DRL)

- Module Communications Network

- Module Configuration

- Wiring Harnesses

- Anti-Theft - Active

- Anti-Theft - Passive

- Multifunction Electronic Modules

- Front End Body Panels

- Body Closures

- Interior Trim and Ornamentation

- Exterior Trim and Ornamentation

- Rear View Mirrors

- Seating

- Glass, Frames and Mechanisms

- Instrument Panel and Console

- Handles, Locks, Latches and Entry Systems

- Wipers and Washers

- Bumpers

- Safety Belt System

- Supplemental Restraint System

- Body Repairs - General Information

- Body Repairs - Vehicle Specific Information and Tolerance Checks

- Front End Sheet Metal Repairs

- Roof Sheet Metal Repairs

- Side Panel Sheet Metal Repairs

- Rear End Sheet Metal Repairs

- Paint - General Information

- Uni-Body, Subframe and Mounting System

- Suspension System - General Information

- Front Suspension

- Rear Suspension

- Wheels and Tires

- Driveshaft

- Rear Drive Axle/Differential

- Front Drive Halfshafts

- Rear Drive Halfshafts

- Brake System - General Information

- Front Disc Brake

- Rear Disc Brake

- Parking Brake and Actuation

- Hydraulic Brake Actuation

- Power Brake Actuation

- Anti-Lock Control

- Anti-Lock Control - Stability Assist

- Steering System - General Information

- Power Steering

- Steering Linkage

- Steering Column

- Steering Column Switches

- Engine System - General Information

- Engine- 2.5L Duratec (147kW/200PS) - VI5

- Engine Cooling

- Fuel Charging and Controls-2.5L Duratec (147kW/200PS) - VI5

- Fuel Charging and Controls - Turbocharger- 2.5L Duratec (147kW/200PS) - VI5

- Accessory Drive - 2.5L Duratec (147kW/200PS) - VI5

- Starting System- 2.5L Duratec (147kW/200PS) - VI5

- Engine Ignition - 2.5L Duratec (147kW/200PS) - VI5

- Engine Emission Control - 2.5L Duratec (147kW/200PS) - VI5

- Intake Air Distribution and Filtering - 2.5L Duratec (147kW/200PS) - VI5

- Evaporative Emissions

- Electronic Engine Controls

- Automatic Transmission/Transaxle

- Transmission/Transaxle Cooling

- Automatic Transmission/Transaxle External Controls

- Transfer Case

- Exhaust System-

- Fuel System

- Fuel Tank and Lines

- Acceleration Control

- Speed Control

- Climate Control System

- Climate Control

Main Categories

0.0165