Ford Kuga Service ManualFront End Sheet Metal Repairs

Ford Kuga Service ManualFront End Sheet Metal Repairs

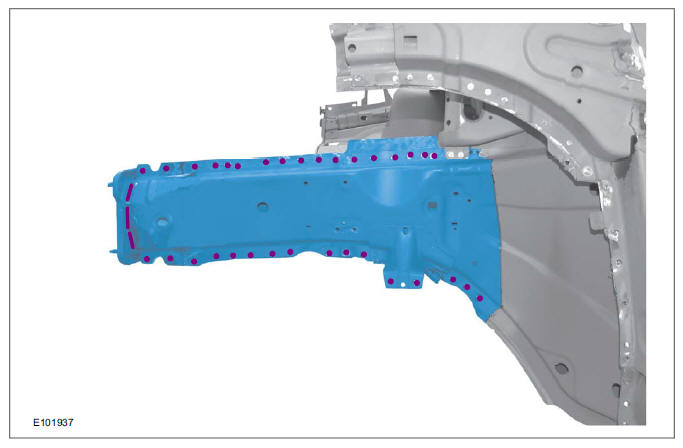

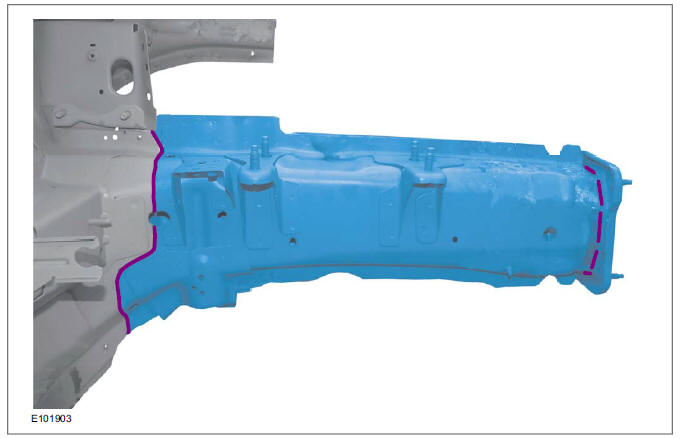

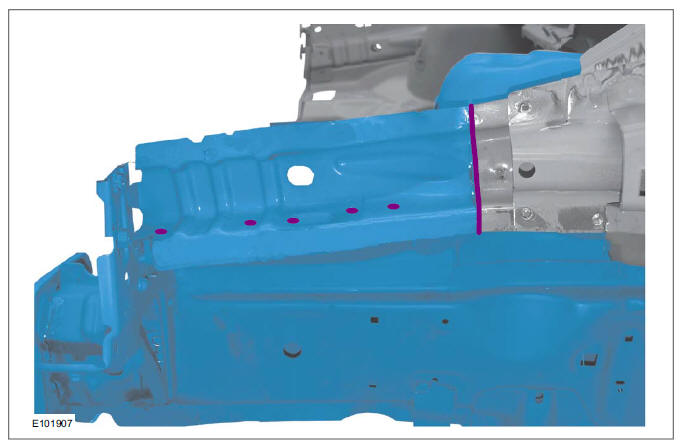

Front Side Member and Fender Apron Panel LH

Front Side Member and Fender Apron Panel LH

Removal

NOTE: Equipment:

Measurement and alignment angle system.

Replacement Parts:

- Inner Side Member

- Outer Side Member

- Apron Panel

- Strut Tower

- Grill Opening Support

- Longitudinal Member Flange Plate

Necessary Removal and Installation Work:

- Fender Apron Panel Reinforcement

Refer to: Fender Apron Panel Reinforcement (501-27 Front End Sheet Metal Repairs, Removal and Installation).

- Reposition the carpeting and the wiring harness away from the working area.

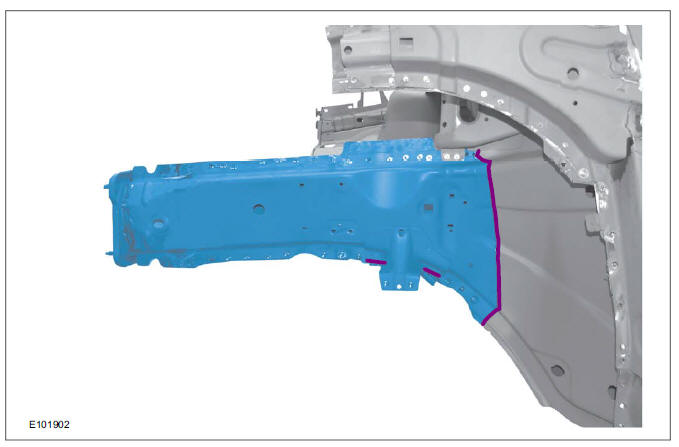

Inner Panel - Fender Apron Panel Reinforcement

- Mark the outline and cut.

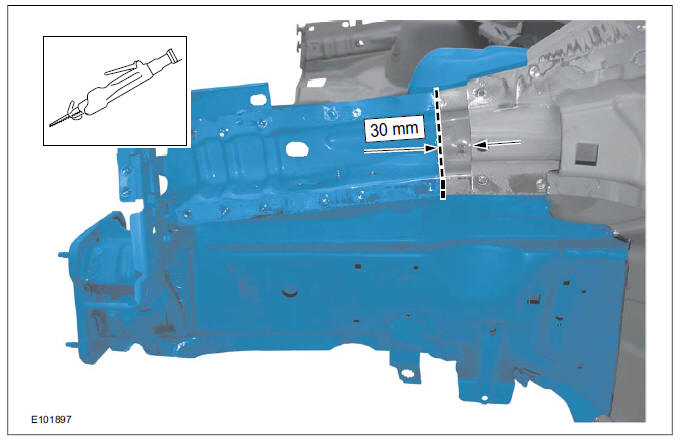

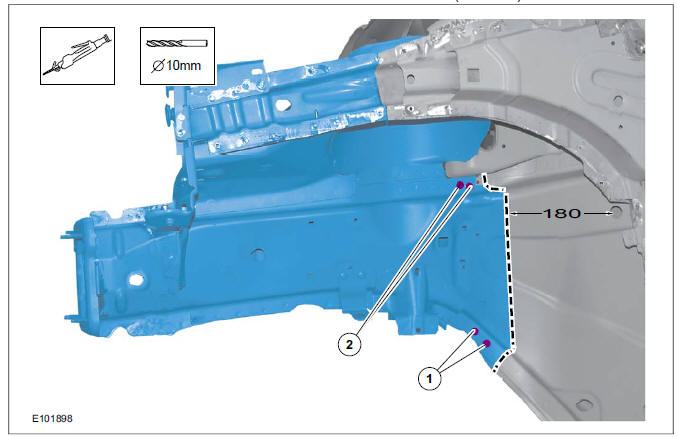

- Front Side Member Outside

- Mark the outline and cut.

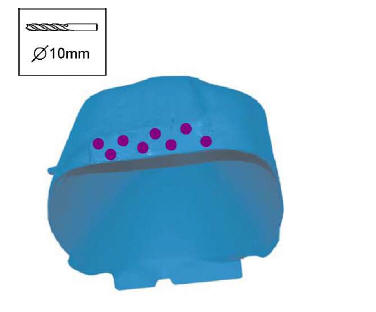

1) Mill out the spot welds (0 10 mm).

2) Mill out the spot welds - Two panel thickness (0 10 mm).

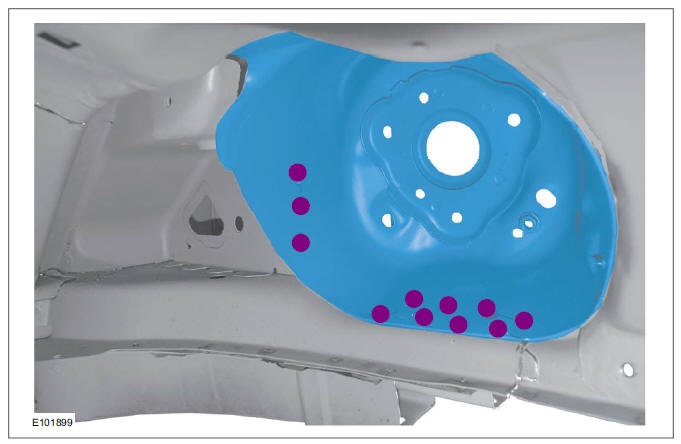

- Strut Tower

- Grind out the spot welds from inside.

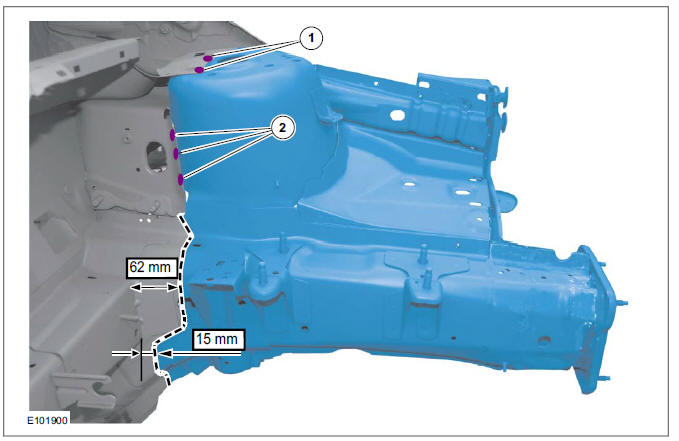

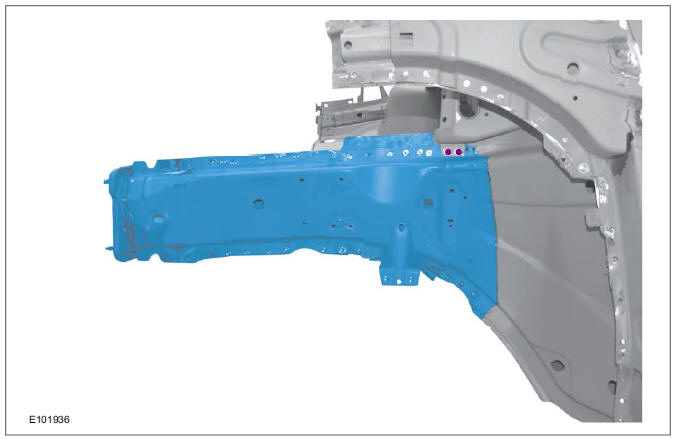

Front Side Member Inside

- Mark the outline and cut.

1) Mill out the spot welds.

2) Mill out the spot welds with a spherical cutter.

Installation

NOTE: Preparation of the replacement parts:

- The required replacement parts needs to be cut out from outer and inner side member replacement part.

- Fit the outer side member, the inner side member and the longitudinal member flange plate and secure them with the alignment angle.

NOTE: Welding

- Before resistance spot welding of body panels with a total panel thickness of 3 mm and greater, the manufacturer's welding equipment instructions and sub-section 501-25 must be followed.

Refer to: Tools and Equipment for Body Repairs (501-25 Body Repairs - General Information, Description and Operation).

- Preparation of the Strut Tower

- Drill holes for puddle welding (0 10 mm).

- Front Side Member Outside

- Resistance spot weld - Panel thickness 3 mm and greater!

- Continuous MIG weld seams.

- Front Side Member Outside

- Drill out by one panel thickness for puddle welding - puddle weld 3 panel layers.

- Front Side Member Outside

- Continuous MIG weld seams.

- Front Side Member Inside

- Continuous MIG weld seams.

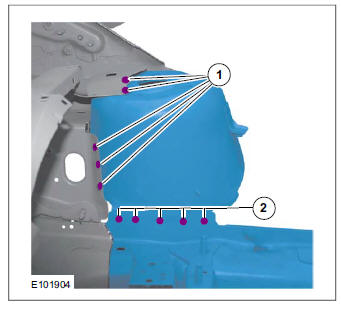

- Strut Tower

- 1) Puddle weld.

- 2) Resistance spot weld - Panel thickness 3 mm and greater!

Strut Tower

1) Puddle weld.

2) Resistance spot weld - Panel thickness 3 mm and greater!

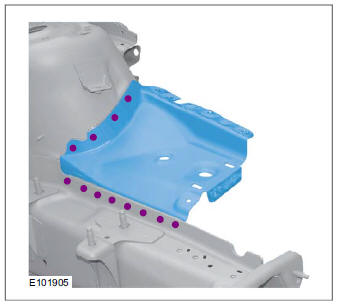

Apron Panel

- Resistance spot weld.

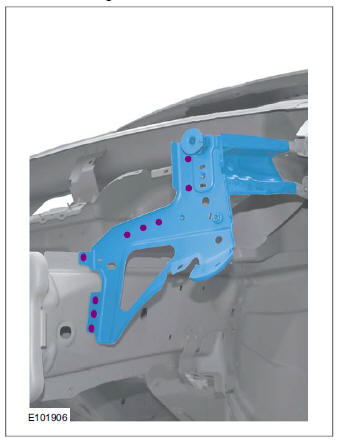

Grill Opening Support

- Resistance spot weld - Panel thickness 3 mm and greater!

Inner Panel - Fender Apron Panel Reinforcement

- Continuous MIG weld seam.

- Resistance spot weld.

Fender Apron Panel Reinforcement

Front Side Member Section

Front Side Member and Fender Apron Panel LH

Front Fender

Fender Apron Panel Section

Ford Kuga Service Manual

- General Information

- Jacking and Lifting

- Noise, Vibration and Harshness

- Suspension System - General Information

- Climate Control

- Auxiliary Climate Control

- Instrument Cluster and Panel Illumination

- Instrument Cluster

- Horn

- Warning Devices

- Parking Aid

- Charging System - General Information

- Battery, Mounting and Cables

- Generator and Regulator

- Voltage Converter/Inverter

- Information and Entertainment System - General Information

- Information and Entertainment System

- Exterior Lighting

- Interior Lighting

- Daytime Running Lamps (DRL)

- Module Communications Network

- Module Configuration

- Wiring Harnesses

- Anti-Theft - Active

- Anti-Theft - Passive

- Multifunction Electronic Modules

- Front End Body Panels

- Body Closures

- Interior Trim and Ornamentation

- Exterior Trim and Ornamentation

- Rear View Mirrors

- Seating

- Glass, Frames and Mechanisms

- Instrument Panel and Console

- Handles, Locks, Latches and Entry Systems

- Wipers and Washers

- Bumpers

- Safety Belt System

- Supplemental Restraint System

- Body Repairs - General Information

- Body Repairs - Vehicle Specific Information and Tolerance Checks

- Front End Sheet Metal Repairs

- Roof Sheet Metal Repairs

- Side Panel Sheet Metal Repairs

- Rear End Sheet Metal Repairs

- Paint - General Information

- Uni-Body, Subframe and Mounting System

- Suspension System - General Information

- Front Suspension

- Rear Suspension

- Wheels and Tires

- Driveshaft

- Rear Drive Axle/Differential

- Front Drive Halfshafts

- Rear Drive Halfshafts

- Brake System - General Information

- Front Disc Brake

- Rear Disc Brake

- Parking Brake and Actuation

- Hydraulic Brake Actuation

- Power Brake Actuation

- Anti-Lock Control

- Anti-Lock Control - Stability Assist

- Steering System - General Information

- Power Steering

- Steering Linkage

- Steering Column

- Steering Column Switches

- Engine System - General Information

- Engine- 2.5L Duratec (147kW/200PS) - VI5

- Engine Cooling

- Fuel Charging and Controls-2.5L Duratec (147kW/200PS) - VI5

- Fuel Charging and Controls - Turbocharger- 2.5L Duratec (147kW/200PS) - VI5

- Accessory Drive - 2.5L Duratec (147kW/200PS) - VI5

- Starting System- 2.5L Duratec (147kW/200PS) - VI5

- Engine Ignition - 2.5L Duratec (147kW/200PS) - VI5

- Engine Emission Control - 2.5L Duratec (147kW/200PS) - VI5

- Intake Air Distribution and Filtering - 2.5L Duratec (147kW/200PS) - VI5

- Evaporative Emissions

- Electronic Engine Controls

- Automatic Transmission/Transaxle

- Transmission/Transaxle Cooling

- Automatic Transmission/Transaxle External Controls

- Transfer Case

- Exhaust System-

- Fuel System

- Fuel Tank and Lines

- Acceleration Control

- Speed Control

- Climate Control System

- Climate Control

Main Categories

0.0198