Ford Kuga Service ManualGeneral Information

Ford Kuga Service ManualGeneral Information

Solvents, Sealants and Adhesives

Solvents, Sealants and Adhesives

Introduction

WARNING: Always handle all solvents, sealers and adhesives with extreme care.

Some contain chemicals or give off fumes which can be dangerous to health. Always follow the manufacturers instructions. If in doubt about any substance, particularly a solvent, DO NOT use it.

CAUTION: If in doubt about the suitability of any proprietary solvent or sealer for a particular application, contact the manufacturer of the product for information regarding storage, handling and application.

The Health and Safety Precautions subsection refers to some commonly used chemicals and materials, hazards associated with their use, and safety measures to be taken.

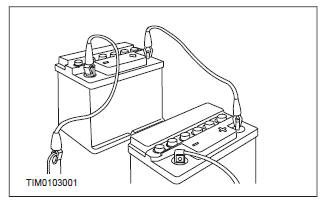

WARNING: Make sure that the ends of the jumper cables do not touch each other or ground against the vehicle body at any time while the cables are attached to the battery. A fully charged battery, if shorted through jumper cables, can discharge at a rate well above 1000 amps causing violent arcing and very rapid heating of the jumper cables and terminals, and can even cause the battery to explode. Failure to follow these instructions may result in personal injury.

Always connect the jumper cables in the following sequence:

- Slave battery positive first and then vehicle battery positive.

- Slave battery negative next and then vehicle ground at least 12 inches (300 mm) from the battery terminal, for example engine lifting eye.

Always reduce the engine speed to idle before disconnecting the jumper cables.

Before removing the jumper cables from the vehicle that had the discharged battery, switch on the heater blower (high) or the heated rear window, to reduce the voltage peak when the cables are removed.

Always disconnect the jumper cables in the reverse order to the connecting sequence and do not short the ends of the cables.

Do not rely on the generator to restore a discharged battery. For a generator to recharge a battery, it would take in excess of eight hours continuous driving with no additional loads placed on the battery.

Component Cleaning

To prevent the ingress of dirt, accumulations of loose dirt and greasy deposits should be removed before disconnecting or dismantling components or assemblies.

Components should be thoroughly cleaned before inspection prior to reassembly.

Cleaning Methods:

- Dry cleaning.

- Removal of loose dirt with soft or cable brushes.

- Scraping dirt off with a piece of metal or wood.

- Wiping off with a rag.

WARNING: Wear eye protection when cleaning vehicle components with compressed air, a steam cleaner or a power washer. Failure to follow this instruction may result in personal injury.

CAUTIONS:

Compressed air is sometimes 'wet' so use with caution, especially on hydraulic systems.

To prevent damage to the electrical connectors in the engine compartment, do not use a steam cleaner or a power washer to clean the engine compartment.

- Blowing dirt off with compressed air.

- Removal of dry dust using vacuum equipment.

This method must always be used to remove friction lining material dust (asbestos particles).

- Steam cleaning.

WARNING: Most solvents require careful handling and some are harmful. Refer to Health and Safety Precautions and to the manufacturers literature for the relevant safety precautions. Failure to follow these instructions may result in personal injury.

Various solvents are available which are suitable for component cleaning. Some components, such as brake hydraulic parts and electrical assemblies should be cleaned only with recommended solvents - refer to Solvents, Sealers and Adhesives or to the section of the manual relevant to the component.

Calibration of Essential Measuring Equipment

WARNING: Equipment, which requires regular calibration, must be calibrated in accordance with the manufacturers

About This Manual

Symbols Glossary

Steering System Health and Safety Precautions

Health and Safety Precautions

Standard Workshop Practices

Solvents, Sealants and Adhesives

Road/Roller Testing

Air Conditioning (A/C) System Health and Safety Precautions

Battery and Battery Charging Health and Safety Precautions

Brake System Health and Safety Precautions

Engine Cooling System Health and Safety Precautions

Window Glass Health and Safety Precautions

Petrol and Petrol-Ethanol Fuel Systems Health and Safety Precautions

Supplemental Restraint System (SRS) Health and Safety Precautions

Body Repair Health and Safety and General Precautions

Ford Kuga Service Manual

- General Information

- Jacking and Lifting

- Noise, Vibration and Harshness

- Suspension System - General Information

- Climate Control

- Auxiliary Climate Control

- Instrument Cluster and Panel Illumination

- Instrument Cluster

- Horn

- Warning Devices

- Parking Aid

- Charging System - General Information

- Battery, Mounting and Cables

- Generator and Regulator

- Voltage Converter/Inverter

- Information and Entertainment System - General Information

- Information and Entertainment System

- Exterior Lighting

- Interior Lighting

- Daytime Running Lamps (DRL)

- Module Communications Network

- Module Configuration

- Wiring Harnesses

- Anti-Theft - Active

- Anti-Theft - Passive

- Multifunction Electronic Modules

- Front End Body Panels

- Body Closures

- Interior Trim and Ornamentation

- Exterior Trim and Ornamentation

- Rear View Mirrors

- Seating

- Glass, Frames and Mechanisms

- Instrument Panel and Console

- Handles, Locks, Latches and Entry Systems

- Wipers and Washers

- Bumpers

- Safety Belt System

- Supplemental Restraint System

- Body Repairs - General Information

- Body Repairs - Vehicle Specific Information and Tolerance Checks

- Front End Sheet Metal Repairs

- Roof Sheet Metal Repairs

- Side Panel Sheet Metal Repairs

- Rear End Sheet Metal Repairs

- Paint - General Information

- Uni-Body, Subframe and Mounting System

- Suspension System - General Information

- Front Suspension

- Rear Suspension

- Wheels and Tires

- Driveshaft

- Rear Drive Axle/Differential

- Front Drive Halfshafts

- Rear Drive Halfshafts

- Brake System - General Information

- Front Disc Brake

- Rear Disc Brake

- Parking Brake and Actuation

- Hydraulic Brake Actuation

- Power Brake Actuation

- Anti-Lock Control

- Anti-Lock Control - Stability Assist

- Steering System - General Information

- Power Steering

- Steering Linkage

- Steering Column

- Steering Column Switches

- Engine System - General Information

- Engine- 2.5L Duratec (147kW/200PS) - VI5

- Engine Cooling

- Fuel Charging and Controls-2.5L Duratec (147kW/200PS) - VI5

- Fuel Charging and Controls - Turbocharger- 2.5L Duratec (147kW/200PS) - VI5

- Accessory Drive - 2.5L Duratec (147kW/200PS) - VI5

- Starting System- 2.5L Duratec (147kW/200PS) - VI5

- Engine Ignition - 2.5L Duratec (147kW/200PS) - VI5

- Engine Emission Control - 2.5L Duratec (147kW/200PS) - VI5

- Intake Air Distribution and Filtering - 2.5L Duratec (147kW/200PS) - VI5

- Evaporative Emissions

- Electronic Engine Controls

- Automatic Transmission/Transaxle

- Transmission/Transaxle Cooling

- Automatic Transmission/Transaxle External Controls

- Transfer Case

- Exhaust System-

- Fuel System

- Fuel Tank and Lines

- Acceleration Control

- Speed Control

- Climate Control System

- Climate Control

Main Categories

0.0147