Ford Kuga Service ManualPaint - General Information » Tools and Equipment for Paint Repairs

Ford Kuga Service ManualPaint - General Information » Tools and Equipment for Paint Repairs

Filler and spray guns

Filler and spray guns

NOTE: Regular maintenance, cleaning after use and careful handling of all individual parts of the spray gun are essential for a high-quality paint finish. The spray gun is the most important implement in the paint shop. Application of paint using the spray gun can produce a layer with absolutely constant thickness and a smooth paint surface.

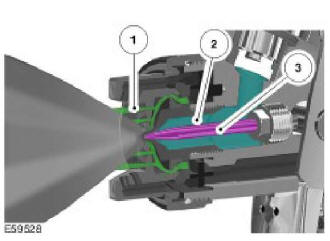

Principle of operation

| Item | Description |

| 1 | Air supply |

| 2 | Paint supply |

| 3 | Nozzle needle |

Because of the construction design and with the aid of compressed air, a spray-ready paint mixture is dragged out of the container to the nozzle by the venturi effect, and is applied to the surface being worked.

When the trigger of the spray gun is pressed to the first pressure point, only the compressed air passage opens. If the trigger is pressed further, the nozzle needle displaces and the air stream drags paint with it at high speed. This produces a spray mist consisting of micro-droplets of paint.

Types of spray gun

| Item | Description |

| 1 | Suction-beaker spray gun |

| 2 | Flow-beaker spray gun |

In the flow-beaker spray gun, the paint container is mounted above the spray gun. On the suction-beaker spray gun, it is below.

Furthermore, spray guns are categorized by their air pressure requirement into high and low pressure guns.

High pressure guns have the disadvantage that they exhibit high consumption of energy and materials. The spray pressure they require is between 1 - 6 bar.

Because of the high air pressure and the large amount of air needed, the result is a powerful paint mist formation (paint transfer rate approx. 35%).

Current practice is mainly to work with reduced mist spray systems (RP and HVLP systems).

Reduced pressure (RP) guns are optimized high pressure guns which have an input pressure at the gun of approx. 2.5 bar and an atomization pressure at the air cap of 1 - 2 bar. In practice this spray technology is preferred for spraying clear lacquer because of the finer atomization.

Low pressure guns have the advantage that they exhibit minimal paint mist formation and because of this the paint transfer rate rises to approx. 65%.

The spray pressure required in this case is between 1 - 5 bar. Nozzle sizes from 1 - 2.2 mm can be used.

HVLP spray guns

| Item | Description |

| 1 | Quantity control |

| 2 | Working pressure control |

| 3 | Spray pattern control |

The high volume low pressure (HVLP) spray gun is a high performance spray gun which forms a soft, fine and homogenous spray pattern. The atomization pressure at the air cap is 0.7 bar when the input pressure at the gun is 2.0 bar.

The low atomization pressure of 0.7 bar together with greatly reduced spray mist provide high material ejection. The low nozzle internal pressure minimizes rebound of the paint droplets from the object and thus the proportion of overspray.

This spray technology has a very high application efficiency. By matching the size of the nozzle, the HVLP spray gun can be used for all repair painting materials.

HVLP spray guns are often used in practice for the application of water based paints.

Mini spray guns are often used for small, localized touching-up work. Use of HVLP spray technology and nozzle sizes of 0.3 - 1 .2 mm permits very fine work, so that the area of the repair can be kept as small as possible.

In order to ensure that a spray gun operates efficiently for a long time, careful cleaning is absolutely vital after use.

NOTE: During cleaning you must distinguish between water based and solvent based materials.

Cleaning by hand: Empty the paint beaker immediately after use.

Flush the gun with cleaner.

Clean it inside and outside with a brush.

Dismantle the gun to clean it thoroughly.

Clean the air cap using a suitable brush.

Use nozzle cleaning needles to clean bores and nozzles.

A spray gun washing machine is recommended if the painting work is highly intensive.

New types of paint processing systems are replacing the conventional mixing beaker, filter and spray gun flow beaker. This reduces the amount of solvent required for cleaning and the amount of routine waste which remains.

Paint preparation system (PPS)

| Item | Description |

| 1 | Beaker |

| 2 | Color bag |

With this system, which is suitable for both suction and flow beaker spray guns, only one beaker is required for mixing and painting.

A bag is inserted in the beaker, in which paint can be mixed, processed and stored after use or completely disposed of.

The small quantity of paint remaining in the gun is removed using a minimum quantity of solvent from the pipette bottle.

The amount of cleaner used is reduced because only the spray gun needs to be cleaned.

General work equipment

Filler and spray guns

Hand and machine sanding tools

Polishing and finishing tools

Infrared drying technology

Air dryers

Paint mixing system

Painting cabin

Ford Kuga Service Manual

- General Information

- Jacking and Lifting

- Noise, Vibration and Harshness

- Suspension System - General Information

- Climate Control

- Auxiliary Climate Control

- Instrument Cluster and Panel Illumination

- Instrument Cluster

- Horn

- Warning Devices

- Parking Aid

- Charging System - General Information

- Battery, Mounting and Cables

- Generator and Regulator

- Voltage Converter/Inverter

- Information and Entertainment System - General Information

- Information and Entertainment System

- Exterior Lighting

- Interior Lighting

- Daytime Running Lamps (DRL)

- Module Communications Network

- Module Configuration

- Wiring Harnesses

- Anti-Theft - Active

- Anti-Theft - Passive

- Multifunction Electronic Modules

- Front End Body Panels

- Body Closures

- Interior Trim and Ornamentation

- Exterior Trim and Ornamentation

- Rear View Mirrors

- Seating

- Glass, Frames and Mechanisms

- Instrument Panel and Console

- Handles, Locks, Latches and Entry Systems

- Wipers and Washers

- Bumpers

- Safety Belt System

- Supplemental Restraint System

- Body Repairs - General Information

- Body Repairs - Vehicle Specific Information and Tolerance Checks

- Front End Sheet Metal Repairs

- Roof Sheet Metal Repairs

- Side Panel Sheet Metal Repairs

- Rear End Sheet Metal Repairs

- Paint - General Information

- Uni-Body, Subframe and Mounting System

- Suspension System - General Information

- Front Suspension

- Rear Suspension

- Wheels and Tires

- Driveshaft

- Rear Drive Axle/Differential

- Front Drive Halfshafts

- Rear Drive Halfshafts

- Brake System - General Information

- Front Disc Brake

- Rear Disc Brake

- Parking Brake and Actuation

- Hydraulic Brake Actuation

- Power Brake Actuation

- Anti-Lock Control

- Anti-Lock Control - Stability Assist

- Steering System - General Information

- Power Steering

- Steering Linkage

- Steering Column

- Steering Column Switches

- Engine System - General Information

- Engine- 2.5L Duratec (147kW/200PS) - VI5

- Engine Cooling

- Fuel Charging and Controls-2.5L Duratec (147kW/200PS) - VI5

- Fuel Charging and Controls - Turbocharger- 2.5L Duratec (147kW/200PS) - VI5

- Accessory Drive - 2.5L Duratec (147kW/200PS) - VI5

- Starting System- 2.5L Duratec (147kW/200PS) - VI5

- Engine Ignition - 2.5L Duratec (147kW/200PS) - VI5

- Engine Emission Control - 2.5L Duratec (147kW/200PS) - VI5

- Intake Air Distribution and Filtering - 2.5L Duratec (147kW/200PS) - VI5

- Evaporative Emissions

- Electronic Engine Controls

- Automatic Transmission/Transaxle

- Transmission/Transaxle Cooling

- Automatic Transmission/Transaxle External Controls

- Transfer Case

- Exhaust System-

- Fuel System

- Fuel Tank and Lines

- Acceleration Control

- Speed Control

- Climate Control System

- Climate Control

Main Categories

0.018